Leading the charge on climate

Climate change is the greatest challenge of our times. From the Paris Agreement to Fridays for Future, government and people alike are calling for bold action to take on what has become a universal concern. Polling shows that more and more consumers want businesses to truly ‘walk the walk’ by engaging in sustainable practices. Publishers have been listening. They realize that the sources of climate change are many and are taking positive steps along the entire supply chain. As a paper company, UPM is not simply following this trend, but leading it. That's why we have adopted a bold vision to support the UN's 2030 sustainable development goals (SDGs) through our own 2030 targets.

The SDGs have been formulated to fight climate change, but also to improve the quality of life of everyone on the planet. Our primary objectives range from Clean water and sanitation (SDG 6) to Affordable and clean energy (SDG 7), Climate action (SDG 13) and Life on land (SDG 15). UPM's contribution rests on the belief that people and the environment are profoundly interconnected. We aspire toward a healthier planet, but also a more humane one.

A model that makes a major difference

To take on the global issue of climate change, you need to start in your own backyard. For UPM Communication Papers, this means right at our mills and in our local communities. There is no better example of our ambition to build a circular economy than the UPM Kaukas mill site in Lappeenranta, Finland. Just as we stress the need to thrive together on a global level, the Kaukas plant in Lappeenranta is already pioneering the way forward. It combines a unique model of integrated production while maintaining a symbiotic relationship with the local community. The UPM Kaukas mill site powerfully demonstrates the idea of thriving together, and how a local operation can have a global impact.

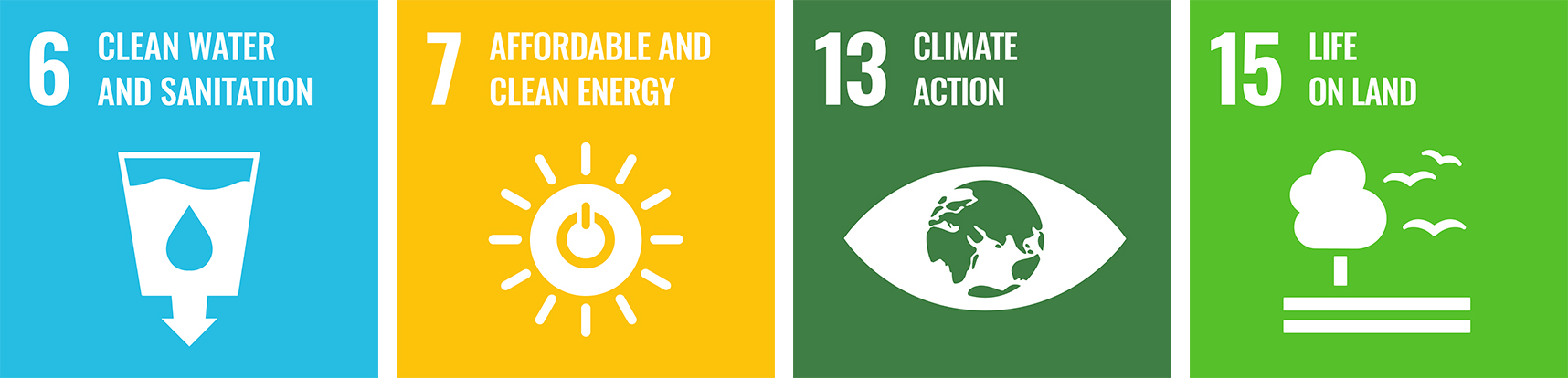

By integrating our mills and biorefinery we not only optimise individual production steps -- we actually leverage their side streams to generate energy for the entire system and to manufacture new products. Much like forests themselves, the integrated mill site is a thriving ecosystem in which all the parts constitute and enrich the whole. The UPM Kaukas pulp mill generates more energy than it needs, so it delivers the surplus energy to the other mills. The associated sawmill delivers bark generated from its processes to Kaukaan Voima Oy’s biopower plant for use as raw material in energy production, while the wood chips and sawdust become raw material for the pulp mill. The biopower plant also receives raw materials from the debarking facilities at the pulp and paper mill. The pulp mill’s residue tall oil is used to manufacture renewable diesel.

Maximizing environmental performance

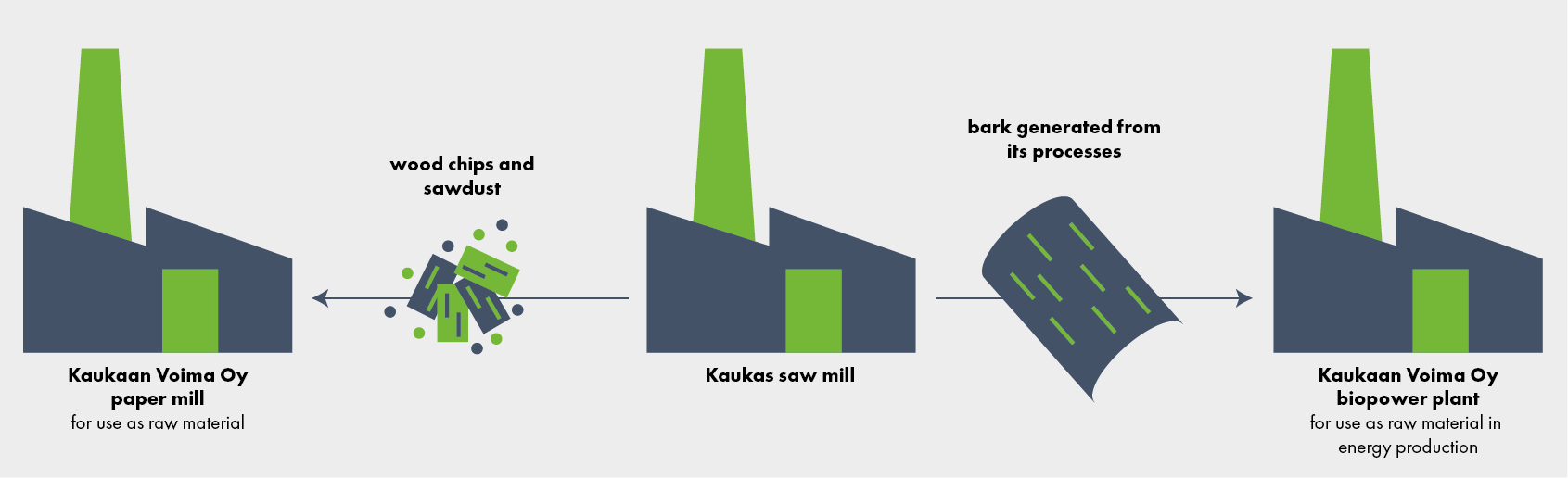

The UPM Kaukas site is thus a prime example of the circular bioeconomy in action. It exemplifies a future, in which the renewable materials from wood are used in the most efficient and sustainable way to meet a range of needs. It is also a critical piece in our efforts to improve overall environmental performance and contribute to UPM’s chosen SDGs. Our production plants predominantly use renewable energy sources and obtain their raw materials from responsibly managed forests. 80% of the energy supplied to the Kaukas integrated mills comes from renewable sources. By 2030, the Kaukas plant also aims to reduce water use by up to 50%.

Moving toward Zero Solid Waste

As a company, UPM strives to eliminate waste by finding new uses for it. The Kaukas site plays a decisive part in our effort to become a Zero Solid Waste company globally by 2030. This means that in the future, we will not deposit any waste at landfill sites or incinerate waste without recovering energy. At the Kaukas site already 89% production residues are reused or recycled either as raw material for other processes or in energy production. At the Kaukas plant, integration and innovation generate value and ultimately improve our competitiveness.

Achieving climate goals together

At UPM Communication Papers, company sustainability has always gone hand in hand with community responsibility. The Kaukas plant and the small city of Lappeenranta, 220 kilometres north of Helsinki, enjoy a perfect symbiosis supported by common goals. A key to Lappeenranta’s success in mitigating climate change is the energy produced using bio-based raw materials from UPM Kaukas. Lappeenranta was jointly awarded the 2021 European Green Leaf Award. Also, Lappeenranta has repeatedly been among the top cities in the international WWF Earth Hour City Challenge, which encourages cities to participate in preventing climate change. UPM plays a significant role in supporting the city’s economy and social well-being. UPM is the city’s single largest private employer and creates indirect jobs in transportation, commerce and construction.

Ultimately, a business can only thrive long-term when its local community does as well. UPM’s close cooperation with Lappeenranta speaks to the potential of tapping into shared goals on a global scale. Megatrends like climate change require a serious commitment to changing how we do business and how we interact with local communities. That’s why ‘Made of sustainability’ is not just a slogan – it’s a call to thriving together.

Author: Christopher Reid